|

|

|

|||||||||||||||||||||||||||||||||||||

| 1) Deselect nZEB actions not to be included in the process | ||||||||||||||||||||||||||||||||||||||

|

|

Tenant Design and Construction Guidelines |

|

Thermography infrared |

|

Indoor Air Quality Assesment | |||||||||||||||||||||||||||||||||

|

|

Energy performance guarantee |

|

Installation renewables | |||||||||||||||||||||||||||||||||||

|

|

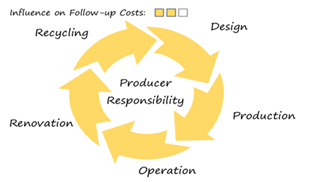

Extended producer responsibility |

|

Eliminate Heat Bridges | |||||||||||||||||||||||||||||||||||

|

|

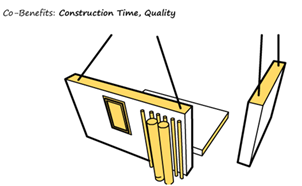

Prefabriction of multifunctional Building Elements |

|

Construction checklists | |||||||||||||||||||||||||||||||||||

|

|

Air Tightness Measurements |

|

Green Power and Carbon Offsets | |||||||||||||||||||||||||||||||||||

| 2) Define main drivers, targets, dates and track the status of the actions throughout the life cycle phase | ||||||||||||||||||||||||||||||||||||||

|

Actions (Task Description) |

Main

driver (Lead) |

Specification

(Quantitative / Qualitative Targets) |

Start Date | Deadline | Status | |||||||||||||||||||||||||||||||||

|

|

3,1 |

|

|

|||||||||||||||||||||||||||||||||||

|

❶Description of the

Action The guidelines will help the future tenants/users/building owner to design and build sustainable interiors and adopt green building practices. I.e. helping them in future build-outs, inerior changes etc. The guidlines could include: - A description of the sustainability features already included in the building. - Information regarding: - Water reduction - Electric lighting and daylighting - HVAC - Energy metering - Indoor air quality and thermal comfort |

❷ Importance: These guidelines are not only helpful for recent users of the building, but also relevant for the "second generation" of occupants. |

❸ Difficulty: Developing guidlines may be easy - it may be harder to encourage the tenants to follow the guidelines. |

❹Standards and

Regulations: - LEED CS-v4 SSc7: Tenant Design and Construction Guidelines - BREEAM NC 2017, 5.0 Management (Commissioning, handover and aftercare) - EN ISO 7730 Ergonomics of the thermal environment – Analytical determination and interpretation of thermal comfort |

||||||||||||||||||||||||||||||||||

|

|

3,2 |

|

|

|||||||||||||||||||||||||||||||||||

|

❶Description of the

Action Energy performance guarantees are similar to energy performance contracts and often part of service contracts, where the owner/occupant pays for a specific service like retrofit measures and gets a guarantee for a better performance or lower energy bill. Energy performance guarantees can so be incorporated into contracts with service providers, contractors or product suppliers (ESCO), transferring some or all of the performance risk to the supplier/ service provider. |

❷ Importance: Energy performance guarantees reduce / outsource project risks, which can be valuable for large and complex retrofits or energy saving investments. |

❸ Difficulty: Transaction costs, financial expert involvement and long negotiation phase could hamper the process to get to these guarantees. |

❹Standards and

Regulations: No regulations or standards are available, but EU-projects like https://ec.europa.eu/energy/intelligent/projects/en/projects/eurocontract#partners to promote EPC |

||||||||||||||||||||||||||||||||||

|

|

3,3 |

|

|

|||||||||||||||||||||||||||||||||||

|

❶Description of the

Action Buildings use large amounts of materials and produce a lot of waste. Extended Producer Responsibility (EPR) policies are based on the principle that producers are responsible for the treatment or disposal of their products at the end-of-life. EPR uses financial incentives to encourage manufacturers to design products that respect the environment, holding producers responsible for the costs of handling their products at the end of their useful life. |

❷ Importance: Energy shortages and pollution prevention are concerns at regional and global levels, while material shortages occur in some regions. |

❸ Difficulty: Set up of regulatory, economic or information instruments. |

❹Standards and

Regulations: - OECD: Extended Producer Responsibility. Updated Guidance for Efficient Waste Management. Published on September 20, 2016. - EPD (Environmental Product Declaration) - standards EN ISO 14025 and EN 15804 |

||||||||||||||||||||||||||||||||||

|

|

3,4 |

|

|

|||||||||||||||||||||||||||||||||||

|

❶Description of the

Action Constructing a NZEB evokes different sources of errors and interface problems. For example the installation of a heavy triple-glazed passive house window into the wall is not a simple task and requires knowledge of how to do it without causing thermal bridges, leakages etc. One answer to such kind of possible errors in building constructions is prefabrication, means the assembling of bigger elements like wall, ceiling or even heating or ventilation systems, in a more controlled way with lower possibilities to make errors. Such prefabricated building elements do not only have the advantage of quick, qualitatively high and precise assembling, they can even provide different functionality such as integrated renewable energy generation, ventilation ductwork, insulation and transparent components - all in one prefabricated wall-element. Another example are solar thermal collectors in roof elements where they produce hot water but at the same time protect the building from weather. There is a growing market for the use of prefabricated multifunctional building elements in NZEBs. The EU and different national programmes support the development of these, because they believe in the increase of quality and functionality for constructions. |

❷ Importance: - Prefabricated construction and HVAC elements increase the construction and functional quality of the NZEB buildings. - The possibilities to include different functions in one element decreases prizes. - The working conditions for processing the elements is mostly much better than on site. |

❸ Difficulty: - A lot of know-how and special equipment is needed to design and construct such elements. - This and the lack of knowledge on the costumer's side may lead to higher launching, convincing and organisational investments than normally calculated for construction works. |

❹Standards and

Regulations: - IEA EBC Annex 50 developed a "10 steps guide" for prefabricated element walls under https://nachhaltigwirtschaften.at/resources/iea_pdf/iea_ecbcs_annex_50_anhang5-10stepsguideline_aee-en_1-3.pdf?m=1469661023 - Regulations or standards on quality management like ISO 9000-standards or quality assessment ISO 15504 |

||||||||||||||||||||||||||||||||||

|

|

3,5 |

|

|

|||||||||||||||||||||||||||||||||||

|

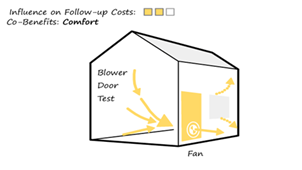

❶Description of the

Action NZEBs are constructed in an airtight way, so that there is are no uncontrollable leakages and air exchange with the surrounding when windows and doors are fully closed. This is first of all because of the ventilation energy losses in winter, but also to get balanced pressure conditions when a mechanical ventilation system will be operated. The building envelope is measured for its airtightness by using the differential pressure method, the so called 'blower door' test. Using this method the remaining air exchange rate can be determined. To do this, air is forced or sucked out into the building under investigation by means of a fan. The fan is usually used with a frame in the opening of an open window. The previously used door (this is where the name comes from) is no longer used as often as the front door should also be checked for windproofness. Due to the generated positive pressure, air flows through leaky constructions to the outside, which can be localized with smoke. With a measuring and control unit, the desired pressure differences can be adjusted and the delivered volume flows can be determined. |

❷ Importance: - The air tightness measurement is a very important quality assurance measure to guarantee the promised functionality of the building envelope. - It is very important to do the testing before the envelope is really finalised, otherwise there is no possibility to optimize the airtightness afterwards. |

❸ Difficulty: - For little buildings it is very easy t do the testing, but for big buildings it is difficult to decide which parts of the buildings are to be tested in one run. - It is costly to get leakages airtight, so there should be put more emphases on that in the planning of the construction before. |

❹Standards and

Regulations: - Thermal performance of buildings - Determination of air permeability of buildings - Fan pressurization method (ISO 9972:2015) - Thermal performance of buildings and materials - Determination of specific airflow rate in buildings - Tracer gas dilution method (ISO 12569:2017) - Different national procedures regarding energy performance certification |

||||||||||||||||||||||||||||||||||

|

|

3,6 |

|

|

|||||||||||||||||||||||||||||||||||

|

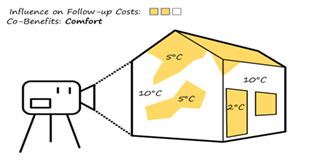

❶Description of the

Action Thermographic investigations are carried out in the form of temperature and heat measurements in all areas of heating, ventilation, air conditioning and refrigeration. In the field of building physics, for example, they serve to determine thermal bridges. Especially in the case of component connections, heat-bridge-related heat losses and lower room-side surface temperatures occur, which can lead to mould fungus formation. Modern devices feature 12-bit high-speed color systems with real-time temperature measurement and display and are equipped with built-in data logging systems. This allows the thermal images to be analyzed and documented via PC. From the small color handycam to the long-wave Stirling cooled real-time camera to the Focal Plane Array system, all thermal and geometric resolution performance requirements are available. Pictures can be taken by a hand-borne camera but also using a drone that carries the camera along the building surface. Low level infrared thermography can be done using a simple thermographic camera at the appropriate weather conditions. High level infrared thermography is usually offered as a service by technical offices for building physics. In this case, the outcome are not only photographs but also an analyis and interpretation of the results in form of a thermographic report. |

❷ Importance: - Infrared thermography helps to reveal heat bridges and deviations in surface temperature - It is a fast, low cost and non-destructive investigation method - One image covers a large area and and can include inaccessible places (via drones) - Images can be stored as photograph for documentation |

❸ Difficulty: - A special camera is needed - Heat bridges can only be identified in the heating season (heating on, cold outside) - Differing emissivities and reflections from other surfaces limit the accuracy - The results show only the surface and not temperature inside the walls |

❽ Methodology/

Technology/ Business Model Infrared Thermography here is mainly used in three occasions: - Investigation in case of mould and other structural damages - Control at the handing over of the construction - Baseline investigation before doing a renovation It can be financed by the assicuration in case of damage, and paid back by future energy savings and prevention of damage in other cases. Infrared thermography is a standard procedure in case of damage. It is however not often used for quality assurance and pre-renovation analysis, since it has not yet been included in the standard procedure. |

||||||||||||||||||||||||||||||||||

|

|

3,7 |

|

|

|||||||||||||||||||||||||||||||||||

|

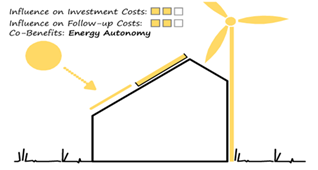

❶Description of the

Action Integration of renewables in the building for various applications such as water heating, heating/cooling and electricity production is an important aim, pursued by the EU and many regions in Europe. Renewable energy technologies are: wind generators, photovoltaic systems, solar thermal water heating, biomass heating, biomass CHP, and different source heat pumps. The Renewable Energy Directive (RED 2014/53/EU) established an overall policy for the promotion of the energy production from renewable sources. It requires the Member States to fulfill at least 20% of its total energy consumption with energy from renewables by 2020. Also, it requires that at least 10% of transport fuels come from renewable sources. The 20% target was updated in November 2016. The new target requires at least 27% of energy from renewable energy sources in the final energy consumption of the EU by 2030. |

❷ Importance: The main goals of installation of renewable energy technologies are to reduce the use of fossil resources and lower CO2-emissions. |

❸ Difficulty: - Technical feasibility studies have to be done: geometry, orientation, position, etc. - Economical viability: capital and maintenance costs, payback time |

❹Standards and

Regulations: Renewable Energy Directive (RED) 2009/28/EC and a lot of technology-specific standards on renewable energy systems |

||||||||||||||||||||||||||||||||||

|

|

3,8 |

|

|

|||||||||||||||||||||||||||||||||||

|

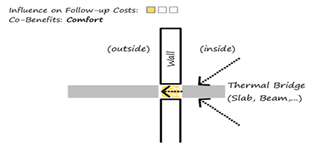

❶Description of the

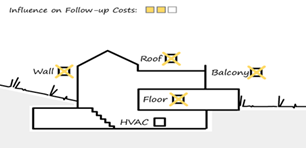

Action Thermal bridges are areas of the building envelope with a much lower thermal resistance than the adjacent wall and ceiling parts. They generally occur in the vicinity of structural connections, for example in the case of balcony projections or roof / exterior wall connections and other component connections. Thermal bridges cause heat losses and lower room-side surface temperatures, which can lead to condensation and mould formation, depending on the room air humidity. Using simulation tools (e.g. HTflux), the resulting lowest room-side surface temperature can be calculated as well as the humidity level that offsets condensation and the thermal bridge loss coefficient. The unit of the thermal bridge loss coefficient is W/(m K), that means lost Watt per running Meter and Kelvin temperature difference between the in- and outside. |

❷ Importance: - The absence of heat bridges reduces thermal energy loss - Elimination of heat bridges helps to avoid structural damage |

❸ Difficulty: - Heat bridges need to be detected before they can be eliminated: Measurement/Calculation before Elimination - For repair works it might be necessary to enter the apartments - Elimination of heat bridges might require adaptations in the building design |

❹Standards and

Regulations: - Restrictions for thermal bridges are usually regulated in the national building code, via maximum energy consumption and minimum allowed surface temperature to avoid damage by condensation - ISO 10211:2017 Thermal bridges in building construction -- Heat flows and surface temperatures -- Detailed calculations |

||||||||||||||||||||||||||||||||||

|

|

3,9 |

|

|

|||||||||||||||||||||||||||||||||||

|

❶Description of the

Action An energy-efficient house provides cosy warmth in winter and a pleasant climate in summer. For everything to work well, special rules must be followed: Modern insulation methods, alternative heaters and solar systems must be perfectly installed and coordinated. Many craftsmen make mistakes here, which can lead to serious defects in the house - even often at first after years. Especially in view of the increasing complexity of projects and the many different actors involved in planning, but above all in implementation, quality assurance measures are of essential importance. In particular, the "invisible" defects, which can lead to major impairments in use and for the user, can only be detected by measurements - and thus remedied before commissioning. Furthermore, the planned energy performance can only be achieved if the building envelope has the appropriate impermeability. Here, too, a measurement is required for verification. Such a quality assurance based on measurements must be planned at an early stage and the corresponding responsibilities defined. - Inspection of building quality - Measurements to prove correct execution - IBM for correct functioning of the HVAC - Monitoring for optimization and early detection of errors |

❷ Importance: - Quality assurance - Prevention of construction defect's - Assurance for a high energetic performance |

❸ Difficulty: - Identify the critical points in the construction process - Communication with construction companies |

❹Standards and

Regulations: Basis is the ISO-9000-family, plus EN 14001 Environmental Management and EN 16001 Energy Management Systems Quality assurance in renovation: http://www.iee-square.eu/InformationPublications/Reports/SQUARE_QASystem_EN.pdf ❹Standards and Regulations: Basis is the ISO-9000-family, plus EN 14001 Environmental Management and EN 16001 Energy Management Systems Quality assurance in renovation: http://www.iee-square.eu/InformationPublications/Reports/SQUARE_QASystem_EN.pdf |

||||||||||||||||||||||||||||||||||

|

|

3,1 |

|

|

|||||||||||||||||||||||||||||||||||

|

❶Description of the

Action - As stated by EPA (United States Environmental Protection Agency): "Green power is a subset of renewable energy and represents those renewable energy resources and technologies that provide the highest environmental benefit". EPA defines green power as electricity produced from solar, wind, geothermal, biogas, eligible biomass, and low-impact small hydroelectric sources. Customers often buy green power for its zero emissions profile and carbon footprint reduction benefits. (Source: https://www.epa.gov/greenpower/what-green-power) - Carbon offset allows individuals and companies to invest in environmental projects around the world in order to balance out their own carbon footprints. (https://www.theguardian.com/environment/2011/sep/16/carbon-offset-projects-carbon-emissions). |

❷ Importance: - Green power plants are an important part of the renewable energy goals of the EU - Purchasing carbon offsets allows to compensate for the emissions of green house gases, limiting their accumulation in the atmosphere. Carbon offset represents an important connection between economic considerations and environmental issues |

❸ Difficulty: - Lack of regulations, also on green power certificates etc. - Dislocation of responsibility |

❹Standards and

Regulations: - CDM: Clean Development Mechanism - JI: Joint Implementation - EUA: European Union Allowances - VCS: Verified Carbon Standard - Gold Standard - VOS: Voluntary Offset Standard |

||||||||||||||||||||||||||||||||||

|

|

3,11 |

|

|

|||||||||||||||||||||||||||||||||||

|

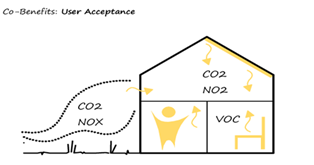

❶Description of the

Action The indoor air quality in new buildings without any ventilation concept could be very bad. For this reason and to increase the indoor air quality, a certain air exchange is necessary. As a guideline, fresh air volume of 25 - 30 m³/h per person is to be offered to rooms when used. Accordingly, the air change rate provides information about indoor air quality; it indicates how often the room air is completely replaced by fresh air per hour. Reference values are: - Apartments: Air change rate of 0.3 - 0.5 per hour - Offices: Air change rate of 1.0 - 2.0 per hour - Meeting / class rooms: Air change rate of 4 to 12 per hour Air velocities are not constant in their natural as well as in mechanical form and, with their degree of turbulence, as well as the indoor air quality, have a considerable influence on the perception of the users. Humans can perceive room air flows of 0.1 to 0.2 m/s as pleasant and will accept them in this range. Humidity is not directly perceived by humans, only a very high relative humidity, 65% or more during summer is perceived as uncomfortably humid. Dry air can cause persistent skin irritation and irritation of the nasal mucosa. At a relative humidity less than 35%, the dust is very favored and plastics are electrically charged. |

❷ Importance: - Stuffy indoor air with high CO2-/VOC- and fine particles-concentration reduces the ability to concentrate when working or learning, it can cause health problems - so the measurement and assessment of the indoor air quality is of high importance - Air quality and comfort sensors are not costly anymore |

❸ Difficulty: - Know how is needed for the assessment and quality check of the indoor air - this leeds to additional costs - Measures to increase the indoor air quality like mechanical ventilation can cause higher investments if not considered from the beginning |

❹Standards and

Regulations: - ASHRAE Standard 55 or ISO 7730 (thermal comfort) - ASHRAE 62.1 and 62.2 or EN15242 / EN 13779 (ventilation rates, contaminant levels) - Some voluntary building certification systems offer guidelines for IAQ |

||||||||||||||||||||||||||||||||||